Application areas

Suitable for use in all areas, especially in high impact conditions and low maintenance environments including the mining, quarry, wood, paper and pulp, recycling, road construction, steel, and transshipment industries.

Availability

Fenner Dunlop UsFlex is available from stock in two tensile strengths; 630/1 6+3 and 1000/2 8+3 in widths up to 2000mm. UsFlex belts are supplied with the abrasion-resistant ‘RS’ cover as standard. The Fenner Dunlop RS cover grade exceeds the very highest DIN and ISO grades (DIN W and ISO 14890 ‘D ‘). Other tensile strengths and cover qualities can be made to order. Available in widths from 400 mm up to 2200 mm.

Belt characterictics

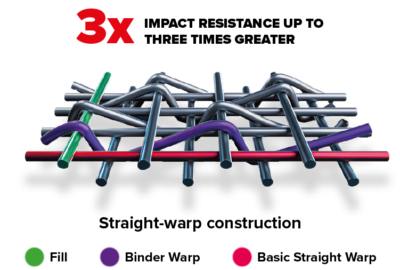

UsFlex owes its outstanding impact and tear resistant characteristics to an innovative woven straight-warp carcass that is unique to Fenner Dunlop. This consists of heavy strands of polyester running lengthwise and heavy nylon strands running crosswise, held in position by a strong yarn. The strands are completely straight in both directions and not interlocked as in a conventional belt carcass. This allows the weft to float free from the warp, thereby minimising the peak point of impact because the energy is absorbed over a larger area, providing maximum protection to the carcass.

FREQUENTLY ASKED QUESTIONS

The ‘secret’ of UsFlex strength is the totally unique ‘straight warp’ inner fabric, which Fenner Dunlop produce in-house in the USA. It consists of heavy lengthwise strands of polyester and heavy crosswise strands of nylon held in position by a strong yarn. The strands are not interlocked so the weft is allowed to float free from the warp thereby ‘gathering up’ to resist ripping and tearing and also allowing energy to dissipate at the point of impact

The rip resistance of UsFlex is more than five times greater than conventional multi-ply belts of a similar tensile strength. Only the rip resistance of the carcass is measured. The covers are removed so the thickness and quality of the covers does not influence the test comparisons.

Finger splicing is required for the single ply construction, although metal fasteners can be used in limited circumstances. A conventional step splice can be used for two-ply UsFlex. However, finger splicing is recommended for both single and dual ply because of the much higher retention (up to 90%) of the belt’s original tensile strength.