Application areas

Fenner Dunlop Superfort significantly exceeds the international standards that have the biggest influence on overall belt strength, splice strength and operational lifetime. These factors include abrasion (wear) resistance, tear strength, tensile strength break for both the carcass and the covers and adhesion between the plies and between the covers and the carcass. It also has particularly good low elongation (low stretch) characteristics.

Superfort ‘long life’ belts provide outstanding reliability and durability in a wide cross-section of industries including cement, chemicals & fertilizers, mining, quarries, power plants, recycling, wood, paper and pulp, sugar & food, steel, and transshipment.

Availability

Fenner Dunlop Superfort belts are available from stock in widths from 400mm up to 2200mm and in tensile strengths from 250 N/mm up to 1000 N/mm. Superfort belts with tensile strengths up to 3150 N/mm can be custom made to order. Superfort belting can be supplied in all Fenner Dunlop cover grades including abrasion resistant, heat resistant, extreme cold, oil resistant, fire resistant and combinations such as heat and oil.

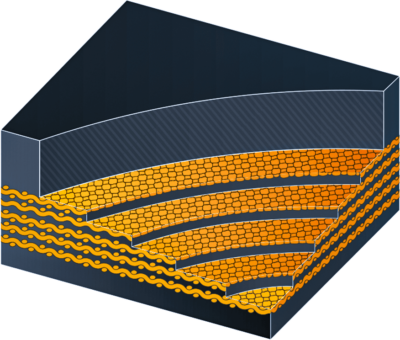

Carcass construction

The Superfort carcass is available with either 2, 3, 4, 5 and 6 synthetic EP (Polyester-Nylon) fabric plies. The EP fabrics that we use are the very best quality available. They are a low stretch and have a consistent longitudinal and transversal tensile strength to provide both first-class handling characteristics and splice strength.

FREQUENTLY ASKED QUESTIONS

The name ‘Superfort’ is the registered brand name used for the range of rubber multi-ply manufactured and supplied exclusively by Fenner Dunlop in The Netherlands. They have been specifically developed to provide the longest possible working lifetime and consequently at the lowest lifetime cost. Superfort is available in a wide range of cover grades (qualities), including abrasion, oil, heat, fire, and extreme cold.

Compared to other belts that claim to be of the same basic specification, every Fenner Dunlop Superfort belt carcass is protected by the very highest quality rubber, including ‘best in class’ resistance to abrasive wear and the damaging effects of exposure to ozone and ultra violet light. Superfort belts significantly exceed the international standards for tear strength, tensile strength, adhesion between the plies and between the covers and good low elongation characteristics.

Fenner Dunlop Superfort ‘long life’ belts are used around the world on a vast variety of applications, from light duty up to the very heaviest, toughest materials and the most challenging working environments.