Opencast mining and ore processing

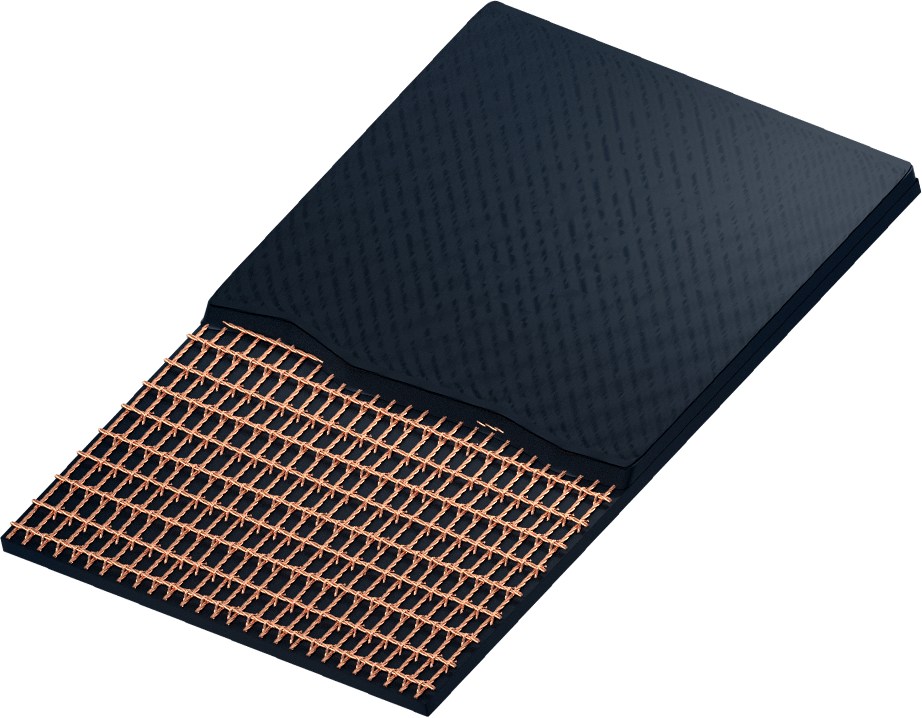

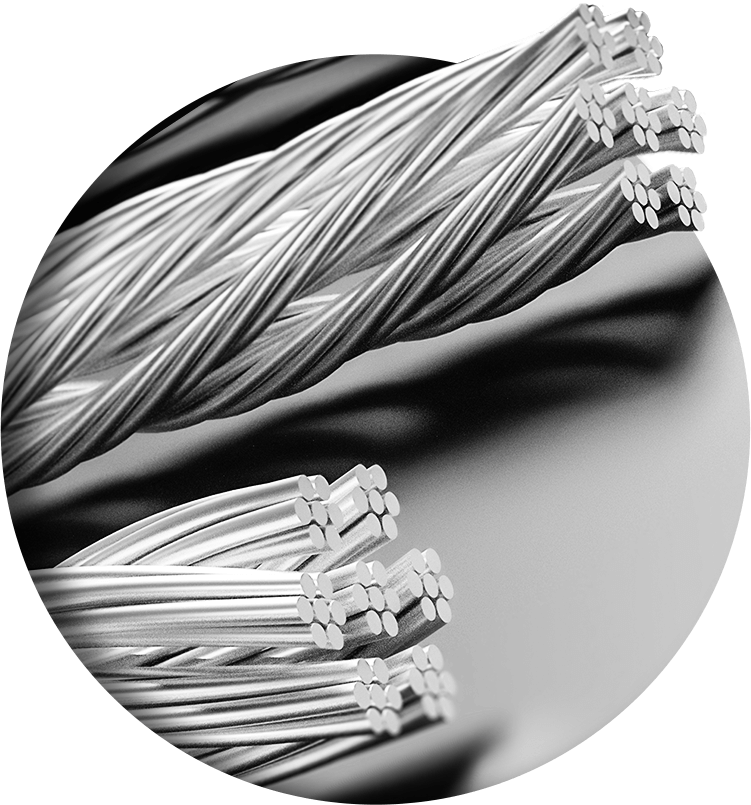

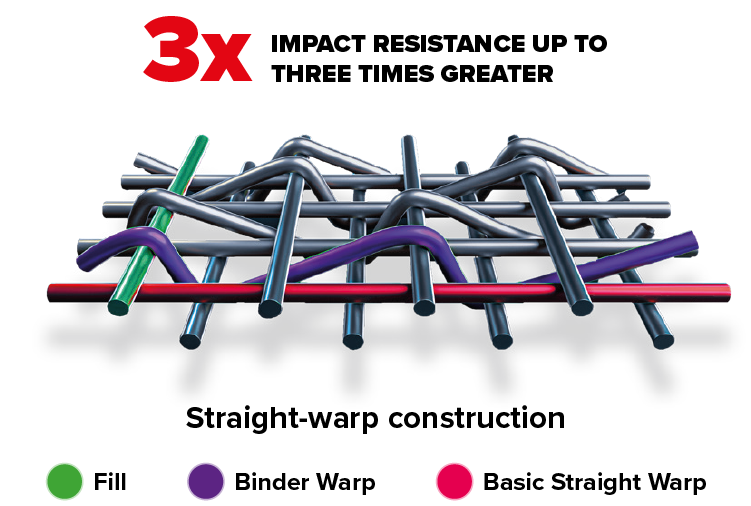

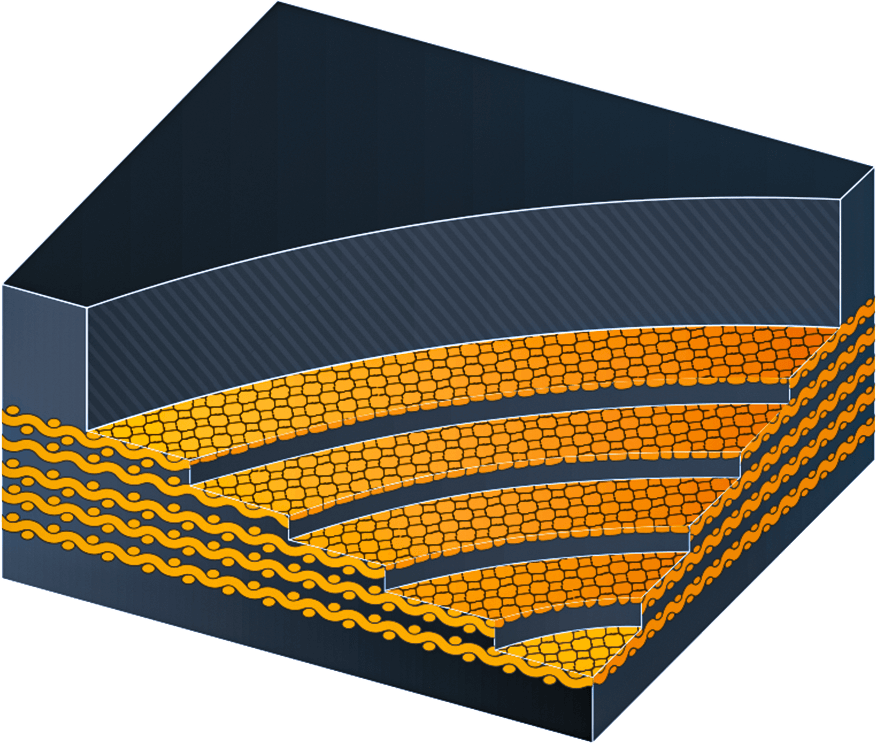

Opencast mining is used to extract a great deal of the minerals used as raw materials by the world’s industries. Conveyors regularly have to cope with an enormous variety of potentially destructive materials, often in some of the most challenging operating conditions imaginable. This requires different types of belting such as belts that have a high resistance to the kind of heavy impact, ripping and tearing that occurs during the primary stages of production through to those designed to withstand the abrasion wear that happens when conveying several thousand tons per hour of fast-moving fines. Over its long history, the engineers at Technobalt have created a wide range of belts that are the toughest, longest-lasting belts that money can buy.

Underground mining

Because safety is of paramount importance, Technobalt belts designed for use within underground mines are fire-resistant and approved and accredited to the appropriate national and international standards. As the inventors and pioneers of fire-resistant conveyor belting, we work very closely with government agencies and national and local mining organizations. Technobalt provides a range of high-quality mining conveyor belts that have outstanding resistance to both abrasion and cutting and designed for use in every phase of the production process – from the mine face and the transportation to the processing location through to the final mixing, blending and stocking. For more information about the different types of belt construction and the different cover grades available please select from the choices below.