Application areas

Ultra X1 is a stronger alternative to 250/2, 315/2 and 400/3 abrasion-resistant multi-ply belts.

Ultra X3 is designed as a stronger alternative to 500/3, 500/4, 630/3 and(630/4 abrasion-resistant multi-ply belts.

Availability

In order to provide the most economical prices possible, Ultra X is only available in full rolls of 300 m or alternatively 2 X 150 m rolls if necessary.

FREQUENTLY ASKED QUESTIONS

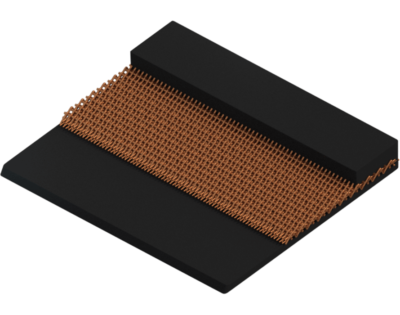

The simple answer is the unique fabric ply that has been developed and is manufactured totally within Fenner Fenner Dunlop. Technically speaking, the fabric uses crimped polyester yarns that provide high strength low stretch. Combined with very strong ‘binder’ and ‘filler’ yarns that create strength and stability under load, the end result is exceptional rip, tear and impact resistance that is far superior to multiple layers of conventional fabric ply.

Although it may take a bit longer, finger splicing has a huge advantage over step splicing because it retains up to 90% of the tensile strength, whereas a step splice will always create a proportional ‘loss’ of tensile strength equivalent to one ply. Another major advantage is that a properly made finger splice will invariably be much stronger and last considerably longer than a step splice

Under normal operating conditions, you can reasonably expect an Ultra X belt to last up to three times longer than the norm. First, there is the unique strength and toughness of the inner carcass. Second is the top quality Fenner Dunlop AA anti-abrasion covers that have excellent resistance to cutting, gouging, and abrasion that outperform typical DIN Y requirements by as much as 20% and which are also 100% resistant to the damaging effects of ozone and ultraviolet light.